Material Applications

Explore the Ideal 3D Printing Material for Your Creative Ventures

3D printing is a world of endless possibilities, facilitated by a diverse range of materials tailored for specific uses. Understanding the nuances of these materials can significantly impact the success of your project. Let’s explore the characteristics of popular 3D printing filaments.

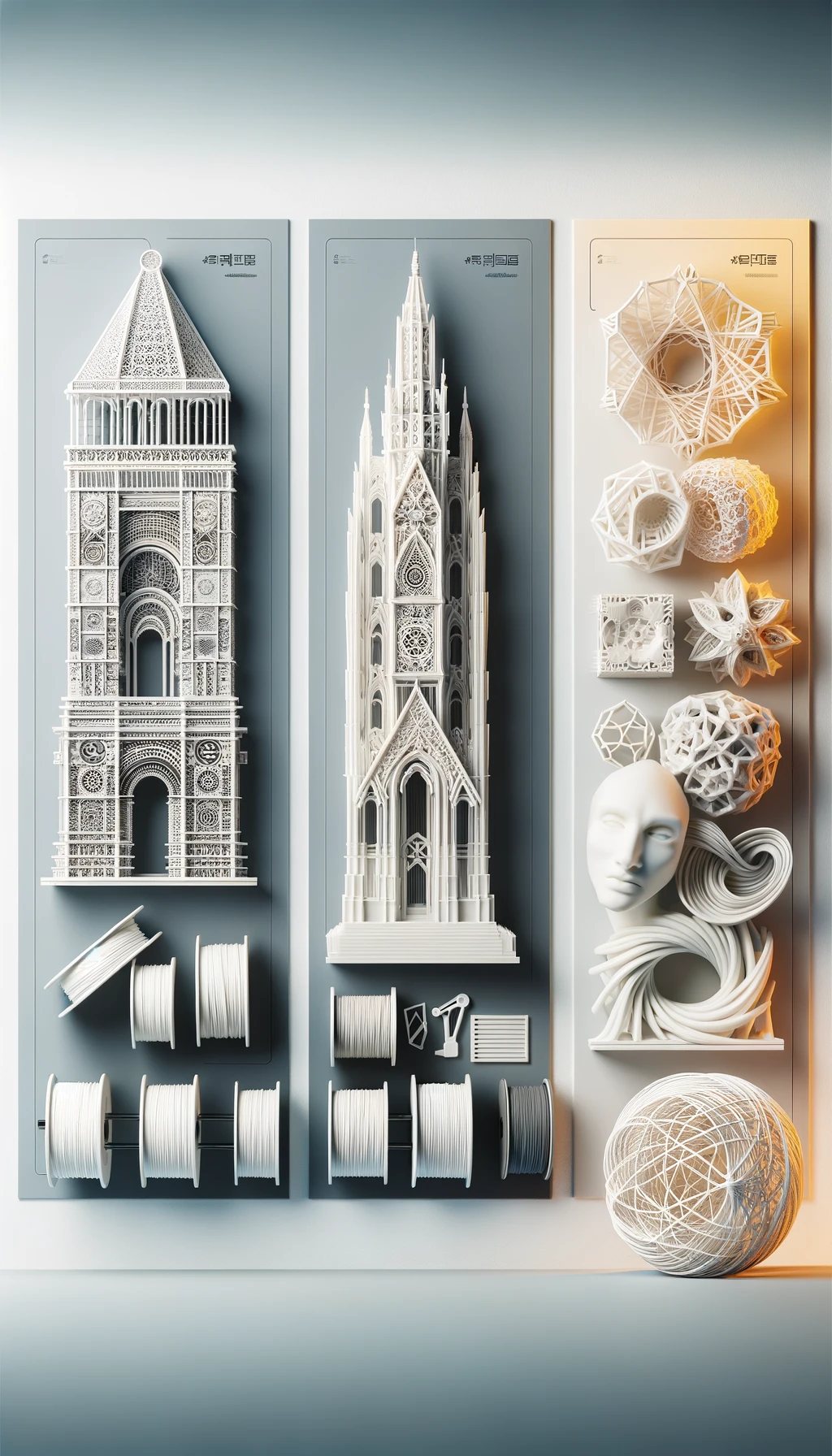

PLA (Polylactic Acid)

Eco-Conscious and Safe:

PLA is a biodegradable and non-toxic material, making it environmentally friendly and safe for home use.

Ease of Printing:

Known for its ease of printing with minimal warping and odor, ideal for beginners. It doesn't necessitate a heated print bed.

Applications:

Best for non-functional prototypes, educational models, and intricate art projects due to its excellent detail rendering.

PLA Plus (PLA+)

Enhanced Durability:

Offers increased strength and durability compared to standard PLA, with better impact resistance.

Slight Heat Resistance:

Has a slightly higher resistance to heat, maintaining ease of printing.

Applications:

Suited for functional prototypes and decorative items requiring a balance of strength and aesthetics.

PLA Pro

Professional Quality:

Exhibits superior strength and durability with improved precision and print quality. Offers better layer adhesion for stronger and more reliable prints.

Applications:

Ideal for more demanding prototypes and end-use parts where a high-quality finish and precision are crucial.

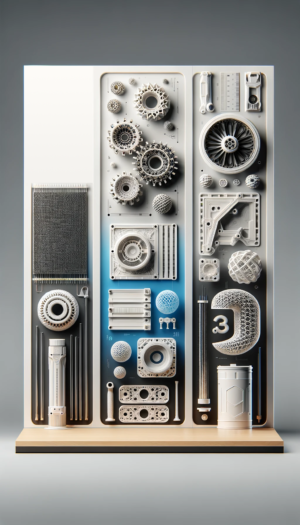

ABS (Acrylonitrile Butadiene Styrene)

Tough and Versatile:

Known for its durability, heat resistance, and slight flexibility. It's a popular choice for more robust applications.

Ventilation Required:

Can emit unpleasant fumes during printing, necessitating good ventilation. Requires a heated bed for effective printing.

Applications:

Automotive parts, electronic housings, toys, and items that need to withstand stress and heat.

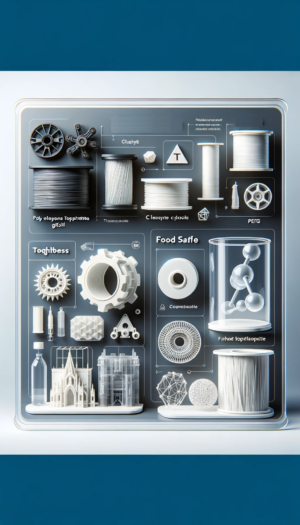

PETG (Polyethylene Terephthalate Glycol)

Balance of Properties:

Combines ease of use with durability, heat resistance, and is less prone to warping than ABS.

Safe for Food Contact:

Offers water-resistant properties and is food-safe, making it ideal for kitchen use.

Applications:

Mechanical parts, functional prototypes, and food-related items like containers and kitchen gadgets.

TPU (Thermoplastic Polyurethane)

Flexibility and Durability:

Known for its flexibility and toughness. Resistant to oils and greases, making it versatile.

Challenging to Print:

Its flexibility can make it more challenging to print, but it's ideal for items requiring elasticity.

Applications:

Perfect for phone cases, flexible wearables, medical devices, and sporting equipment.

Ready to Start Your 3D Journey?

Contact Us for a Customized Quote

Let’s collaborate to make your vision a reality. Reach out for a personalized consultation and quote today.

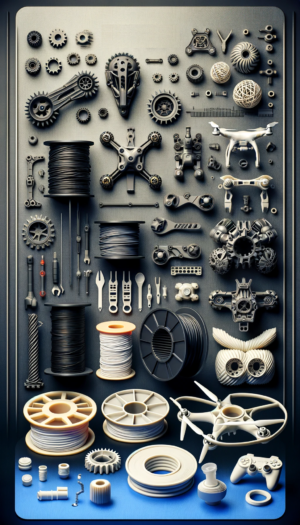

Nylon

Robust and Flexible:

Offers a blend of strength, durability, and flexibility. Exhibits high heat resistance.

Moisture Sensitive:

Tends to absorb moisture, necessitating special storage conditions to maintain its properties.

Applications:

Gears, hinges, mechanical components, and functional tools that require both strength and flexibility.

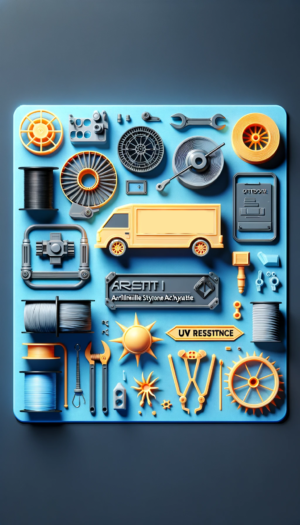

ASA (Acrylonitrile Styrene Acrylate)

For Outdoor Use:

Exceptional UV and weather resistance make it more suitable for outdoor applications compared to ABS.

Applications:

Outdoor gear, automotive exterior parts, sports equipment, and items exposed to sunlight and various weather conditions.

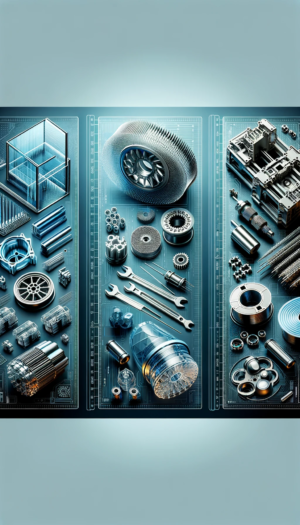

Polycarbonate (PC)

Superior Strength:

Known for its extreme strength and heat resistance, making it ideal for demanding industrial applications.

Printing Challenges:

Difficult to print due to its requirement for high printing temperatures.

Applications:

Protective gear, industrial machinery parts, aerospace components, and high-strength prototypes.

PVA (Polyvinyl Alcohol)

Support Material Extraordinaire:

Water-soluble, primarily used as a support material in complex prints.

Dual Extrusion Compatibility:

Best used with dual-extrusion 3D printers for intricate models.

Applications:

Ideal for complex models with overhangs and detailed architectural and prototype models.

HIPS (High Impact Polystyrene)

ABS Companion:

Similar to ABS, dissolvable in limonene, and used as a support material.

Lightweight and Versatile:

Also serves as a standalone filament for lightweight models.

Applications:

Supports for ABS prints, lightweight models, cosplay items, and props.

Resins

High Detail and Variety:

Used in resin 3D printers, offering high detail and various properties like flexibility and strength.

Applications:

Perfect for jewelry making, dental applications, detailed prototypes, miniatures, and figurines with fine features and high precision.